The type of modern wire rope that is still used today can trace its origins back to the 1830s, but has since then developed to become an integral part of dozens of different industries. It provides a sturdy means for lifting and lowering loads reliably and safely, but also finds other varied uses with things such as electrical cabling or structure support internally in buildings. In the below article and infographic we explain its use across the different industrial sectors.

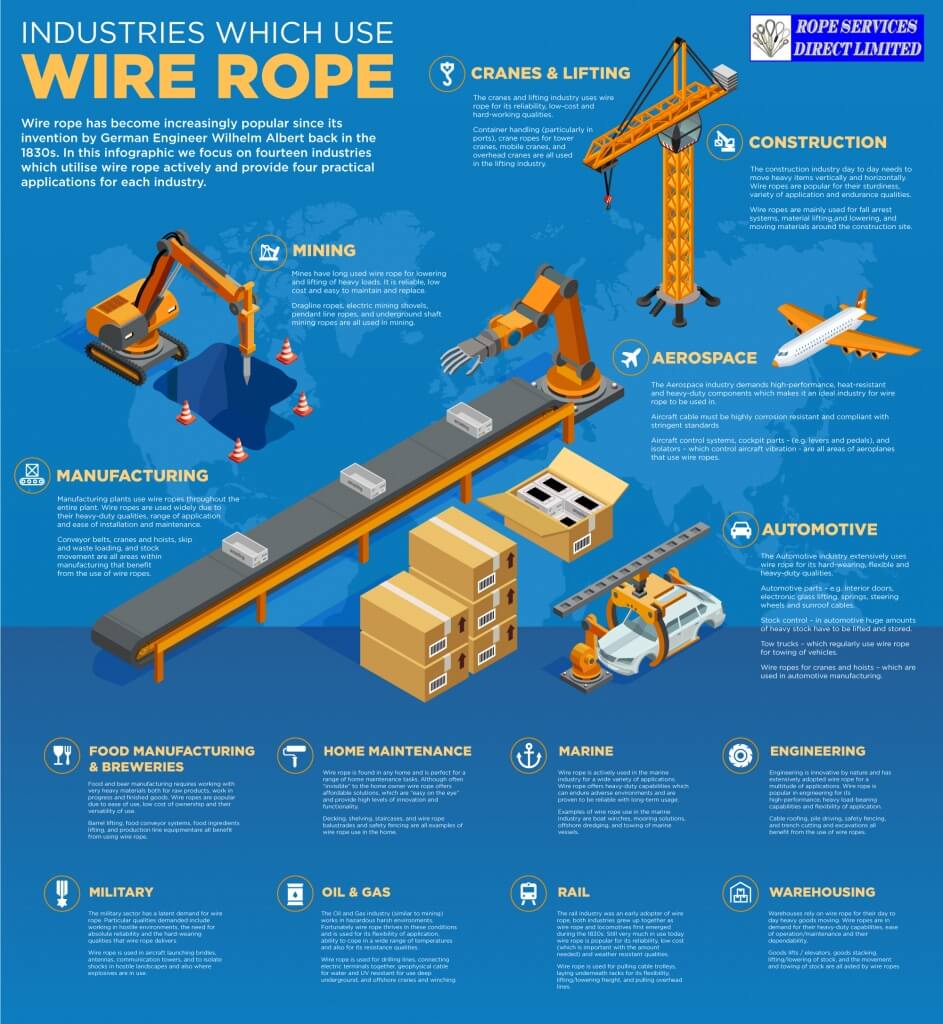

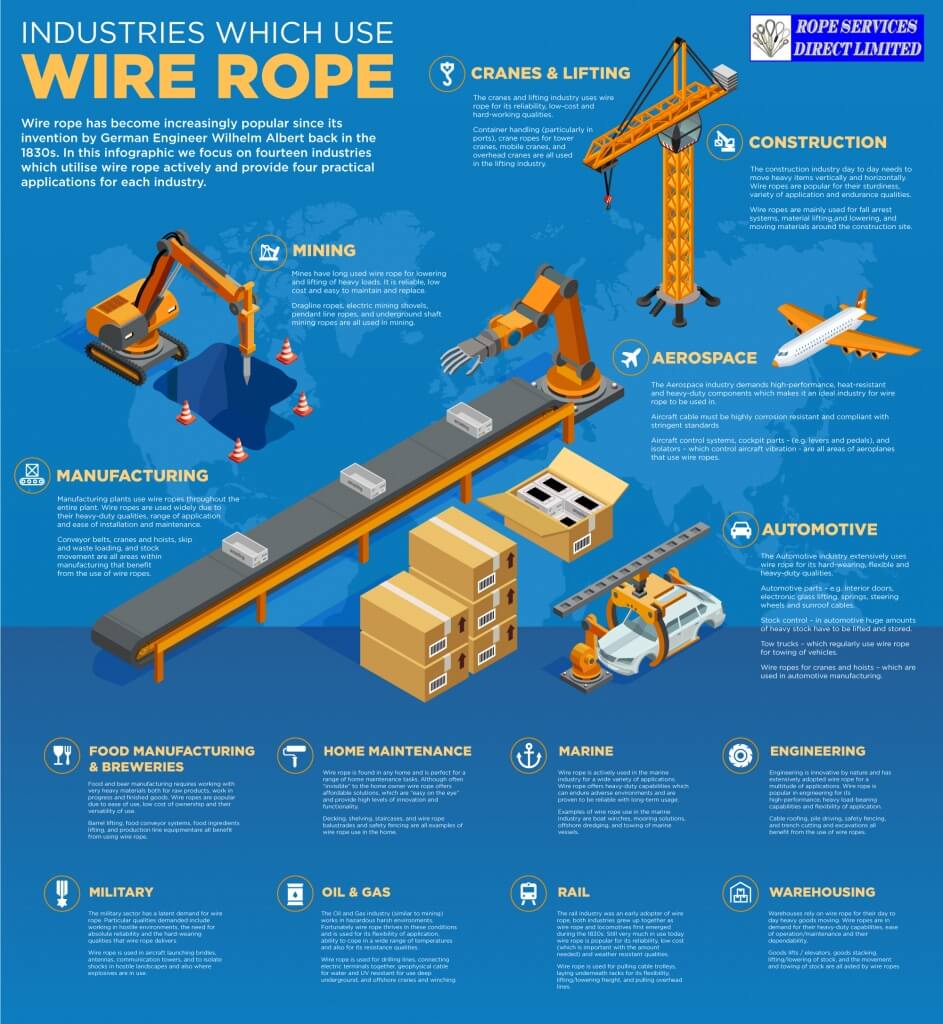

An infographic produced by Rope Services Direct about 14 industries which using the material -

click here to open the full infographic

Wire Rope use in the Aerospace Industry

The

Aerospace industry has always been extremely demanding on parts used which need to be extremely heavy-duty whilst also being resistant to heat and corrosion. We commonly associate the lifting tool with lifting and lowering tasks, but they also find use within the aircraft themselves. They connect the pedals and levers within an aircraft’s cockpit, allowing for the transmission of force between the various mechanisms that allow for the control of the aircraft. This will commonly be seen in the form of a Bowden cable which is highly corrosion resistant, and allows for the control of mechanisms such as the throttle, the propeller pitch, and the cowl flaps. Isolators are also used to minimise and control the vibration with an aircraft.

The material finds great use in the aerospace industry for connecting mechanisms together

Its use in the Automotive Industry

As with the aerospace industry, rope finds use internally within the

automotive industry. It is commonly used in the tyres of an automotive vehicle to reinforce them, thereby increasing strength and durability. As the demand has increased for automotive vehicles in recent years, wire rope has also found a great use in cranes and hoists for helping to increase the efficiency and speed of the production process. Within car factories huge amounts of heavy stock have to be lifted and wire rope is used in this process. It is used in the manufacturing of automotive components such as various cables, exhausts, steering wheels, seats, springs, sunroofs and doors.

Its use in the Construction Industry

The

construction industry is one of the most commonly associated with the lifting and lowering of loads, as well as the movement of materials around the site and therefore the use of rope. Ropes are created with high performance and strength in mind as they are comprised of several wires twisted together into strands, which have then been twisted together.

This means that the rope is able to support a high level of tension, weight load and can be safely run through sheaves and other forms of

lifting gear that is commonly found on a construction site. It is also used as a safety feature within fall arrest systems on construction sites. Common construction projects using rope include suspension bridges or concrete columns.

It is commonly used for suspension bridges in the construction industry

Cranes and Lifting

The material is widely used as the main means of low-cost lifting / lowering and hoisting with cranes and can come finished in

assemblies such as gym cables or rope slings, and with a number of

rope end fittings available such as rope grips and thimbles. This makes the ropes extremely dynamic and can be adapted to a number of lifting situations (e.g. container handling in ports, in tower cranes for skyscraper building, etc.) Their robust and sturdy nature allows them to handle a great deal of weight, and so are extremely useful within the

cranes and lifting industry.

Engineering

Engineering is an innovative industry and has embraced the lifting equipment as it is able to withstand a great deal of crushing, bending, abrasion, and requires lifting weight / load bearing, so finds great use within the engineering industry. Many tasks that need to be completed within the civil engineering industry, such as trench cutting and excavations, drilling, pile driving and grabbing,

heavy-duty cable roofing, safety fences (for fall prevention and security) utilise the material. This is done because the ropes are highly compatible with the machinery and heavy equipment that needs to be used. Such machinery includes cable dredgers, slurry trench cutters, and rotary drilling rigs.

The lifting medium also find a great use as structural cables, and in much the same way as within the construction industry, are of huge benefit to architects. Some projects include bridges, stadiums, and vessels.

Food and Beverages

Food manufacturing and beverage industries (brewing, distilleries, vineyards, etc) extensively make use of wire ropes throughout the production process. Due to the enormous quantities involved weights to be lifted, lowered and moved around are heavy whether it is raw materials, food/beer in manufacture or finished goods. It is frequently used in conveyor systems to convey materials along the conveyor. Cranes and hoists use it to lift and lower food ingredients when needed in the production process. The weight of barrels (e.g. beer, wine, whiskey, etc.) are too heavy to lift manually and once again the lifting medium is actively used to aid lifting barrels.

Home Maintenance

As well as having plenty of industrial use, ropes can also be used in more domestic environments where its low cost is appealing. Rope made from wire is needed in the home for its strength and flexibility but also has the advantage it can be in use whilst also being invisible. Items such as

balustrades and safety fencing can act as both a protective barrier or a contemporary piece of design within a home. It can also be used for decking, in opening garage doors and for hanging shelves or stairs. You can also find rope attached to trees where a strong, sturdy material is needed to hold together two parts of a tree that may be separating over time.

Wire rope balustrades can be used in the home for contemporary looking barriers

Wire Rope Use in the Manufacturing Industry

Manufacturers need to keep costs low; this is just one of the reasons for the extensive use of the lifting medium, as are the ease of installation and ongoing maintenance. The

manufacturing industry requires the use of industrial machinery and cranes factory wide. Lifting equipment such as overhead cranes and hoists utilise ropes which are perfect for assisting in the lifting of heavy loads throughout the entire plant. The constant movement of heavy stock objects (e.g. through conveyor belts) is a primary role within the manufacturing industry, and ropes are more than capable of handling this due to their heavy-duty capabilities. They also assist with the production, packing, skip / waste loading and sales of final products manufactured within this industry.

Its use in the Marine Industry

As with the aerospace or automotive industries, the

marine industry requires the lifting, winching, moving and lowering of incredibly large and heavy parts, and it is one of the best-suited pieces of equipment for this. Many ships within the marine industry, like large container ships, have cranes aboard for the movement of the objects being transported, and rope is commonly used within these cranes. is also useful on occasions when marine vessels need to be towed and is perfect due to its heavy load-bearing capabilities. Offshore dredging is another popular application of wire rope where the ability to work at depths demands the ability to work in adverse environments which rope excels at. Finally, wire rope is also used for yacht rigging and mooring. Sometimes, the mooring of large cargo ships is necessary, and as these weigh a great deal, there is no rope better placed than wire rope to hold the ship safely in place.

Wire Rope Use in the Mining Industry

The material has

long been used in the mining industry, renowned for its hard-wearing qualities, it is also safe, reliable, easy to use / replace and operates at low cost in mines around the world. Machines such as winch ropes are used within the mining industry, and wire ropes are generally used to complete the lifting and lowering that winch ropes do. Alongside this, excavators that are required to be lifted and lowered down into the place that is being mined are subject to incredible stress, and wire rope is manufactured with this in mind. Whether it is surface mining (e.g. pendant line ropes) or underground mining (e.g. dragline ropes), wire ropes are utilised extensively for their reliability and high-strength nature. It is also used in electric mining shovels, which are power shovels enabled through wire rope

Its use in the Military Industry

Machines and equipment used within the

military industry can be subject to incredibly high levels of pressure and stress. Wire rope copes with this admirably;

aircraft launching bridles in aircraft carriers for example use wire rope to launch military aircraft quickly into the air. Whilst; isolators are used to absorb shock and vibrations. This is extremely useful in areas where there may be rough terrain or even explosives, helping to protect the military men involved. Wire rope is also used within the military aeroplanes that are manufactured in the aerospace industry referred to earlier. High-quality military antennas use it to function as do communication towers which use wire rope in their construction.

Its use in the Oil and Gas Industry

Much as with the mining industry, the

oil and gas industry requires machines to be lowered down into very low hazardous depths and to withstand wide-ranging temperatures, large amounts of pressure and stress. The most common uses for wire rope within the oil and gas industry comes with drilling lines for helping to keep oil rigs productive, offshore mooring ropes to help moor or anchor and electromechanical cables which connect electrical terminals together. You will also find that the strength of wire rope makes it the perfect fit for use as geophysical cable, as it can be lowered deep into the Earth’s surface while maintaining water and ultraviolet light corrosion resistance.

Its use in the Rail Industry

Wire ropes are used to pull overhead line conductors, commonly used within the rail industry, over long distances. Early use of overhead line conductors can be seen

dating back to the 1880s, but have since

rapidly improved to meet the new high-speed requirements of railway lines.

As well as with uses in overhead lines, wire rope can also be found

underneath railway tracks, and is useful in situations where obstructions may need to be kept clear from the street or track. This kind of method is still in operation for the

Clay Street Hill Railroad in San Francisco. Wire rope enabled cranes and hoists are frequently used to load freight trains with the produce required for their journeys.

Wire Rope Use in the Warehousing Industry

Due to the high level of strength that wire rope possesses, they are perfect for lifting and lowering applications that cranes are required to do. Cranes and other forms of lifting equipment are used within warehouses for the safe transportation, stacking, storage, and delivery of items, and wire rope is a reliable material for these tasks. Pieces of equipment that may use wire rope are items such as hoists, and they

greatly increase productivity rather than using other manual handling means. Another use of wire rope is in goods elevators which are necessary to ascend or descend warehousing stock from one warehousing level to another.

Wire ropes are used to help move items around a warehouse

Wire rope use in other industries

Although this article focuses on fourteen main industries using the material, there are may other industries which benefit from its use, these include:

- Agriculture and farming – It is popular in farming, particularly for use in barns and also where heavy lifting is required

- Displays – Hanging displays are frequently enabled through the material

- Elevators – It is used as a part of the ascending and descending process

- Exercise Equipment – Many different types of exercise equipment’s benefit from the elastic quality of the material in applications such as gym cables and strength equipment particularly

- Fire-fighting – Heavy lifting requirements of fire fighters are often met with the support of the rope

- Lighting – Frequently lighting can be suspended through the use of ropes

- Luggage – It is actively used in luggage locks and handles

- Railings – Decorative and hard-wearing railings often include the lifting medium

- More too – We have just scratched the surface, there are so many other industry uses!

Want to know more?

As can be seen, the material in question is an incredibly useful invention that plays a part in so many different aspects of our lives, even if we do not always know about it! If you’re interested to know more, please get in

contact with us.

An infographic produced by Rope Services Direct about 14 industries which using the material - click here to open the full infographic

An infographic produced by Rope Services Direct about 14 industries which using the material - click here to open the full infographic

The material finds great use in the aerospace industry for connecting mechanisms together

The material finds great use in the aerospace industry for connecting mechanisms together

It is commonly used for suspension bridges in the construction industry

It is commonly used for suspension bridges in the construction industry

Wire rope balustrades can be used in the home for contemporary looking barriers

Wire rope balustrades can be used in the home for contemporary looking barriers

Wire ropes are used to help move items around a warehouse

Wire ropes are used to help move items around a warehouse