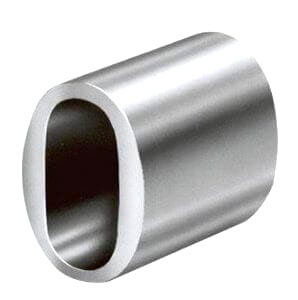

When applied to wire rope assemblies, thin walled carbon steel ferrules will create a tough, chemically stable termination point that can combat all sorts of corrosion and physical distresses. You can order custom thin walled ferrules from Rope Services Direct, along with ferrules of other materials.

Thin Walled Carbon Steel Ferrules – Basic Details

As with any metal ferrule, a thin

walled unit made from carbon steel will fix the end of a wire rope in place and give you the opportunity to add

an attachment or loop it back on itself if necessary.

Thin walled carbon steel ferrules are composed of two materials which complement one another very well. While aluminium ferrules are more widely used, they are not as capable when encountering high operating temperatures. They also succumb to corrosive substances and environments with greater ease. This is why carbon steel ferrules like this are necessary in certain industries.

Safety Benefits of Carbon Steel Ferrules

Our carbon steel ferrules are made with an expert eye for detail and pressed with equipment that ensures a permanent, immovable fit. This helps make safe lifting achievable in any scenario and accounts for the often hostile atmospheres that wire rope assemblies have to face.

Looking for Ferrule Info & Advice?

You may have a lot of queries about the carbon steel thin walled ferrules we sell here at Rope Services Direct. We can offer expert guidance on rope fittings when you get in touch by calling 01384 78004 or emailing us. We aim to reply quickly and accurately every time.

| Wire Rope Capacity Diameter (mm) | Die Identification | ||||||||

| Ferrule Size | Fill Factor (f=0.45-0.52) Fibre Core | Fill Factor (f=0.58-0.60) Steel Core | Dies Marked | Diameter after Pressing | Straight length after pressing approx. | Required pressure approx. | |||

| Min | Max | Min | Max | mm | Tol | mm | kN | ||

| 17 | 16 | 16.8 | 15.5 | 16.3 | 16 | 28.7 | +0.5 | 64 | 1700 |

| 17 | 16.8 | 18.3 | 16.3 | 17.8 | 17 | 29.5 | 0 | 64 | 1700 |

| 19 | 18.3 | 19.3 | 17.8 | 18.7 | 18 | 32.4 | 71 | 2000 | |

| 19 | 19.3 | 20.2 | 18.7 | 19.6 | 19 | 33.3 | +0.6 | 71 | 2000 |

| 21 | 20.2 | 20.9 | 19.6 | 20.3 | 20 | 34.7 | 0 | 78 | 2300 |

| 21 | 20.9 | 21.8 | 20.3 | 21.1 | 21 | 35.2 | 78 | 2300 | |

| 23 | 21.1 | 23.2 | 22 | 39 | 84 | 2700 | |||

| 23 | 22.5 | 24.3 | 23 | 40 | 84 | 2700 | |||

| 25 | 23.6 | 24.5 | 24 | 42.7 | 93 | 3100 | |||

| 25 | 24.5 | 25.5 | 25 | 43.3 | 93 | 3100 | |||

| 27 | 25.5 | 27.5 | 26 | 45.9 | 101 | 3500 | |||

| 27 | 26.7 | 28.5 | 27 | 46.6 | 101 | 3500 | |||

| 29 | 27.9 | 28.8 | 28 | 49 | +0.8 | 119 | 4300 | ||

| 29 | 28.9 | 29.8 | 29 | 50 | 0 | 119 | 4300 | ||

| 31 | 29.9 | 30.8 | 30 | 53 | +1 | 124 | 4900 | ||

| 31 | 30.9 | 31.8 | 31 | 54 | 0 | 124 | 4900 | ||

| 33 | 31.9 | 32.8 | 32 | 55.2 | 132 | 5500 | |||

| 33 | 32.9 | 33.8 | 33 | 56 | 132 | 5500 | |||

| 35 | 33.9 | 34.8 | 34 | 58.5 | 140 | 6500 | |||

| 35 | 34.9 | 35.8 | 35 | 59.5 | 140 | 6500 | |||

| 39 | 37.9 | 38.8 | 38 | 65 | 157 | 7500 | |||

| 39 | 38.9 | 39.9 | 39 | 66 | 157 | 7500 | |||