Lever load binders, chains and hooks are all available from Rope Services Direct, testing and inspections are also available.

About Lever Load Binders

Standard lever load binders are a convenient way of securing cargo. They are used along with chains and hooks. The chain is already securely fixed to the lorry at each end, then the two chains are passed over the cargo and attached to the load binder. The lever is then pulled down in order to pull the chain up tightly.

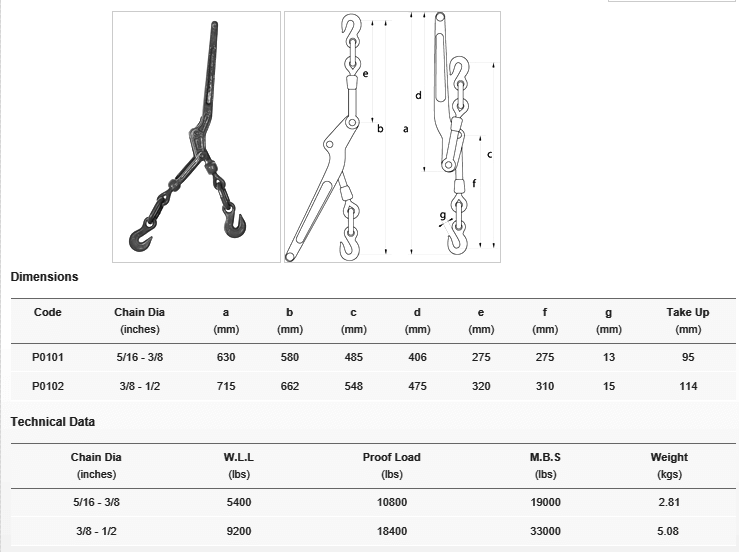

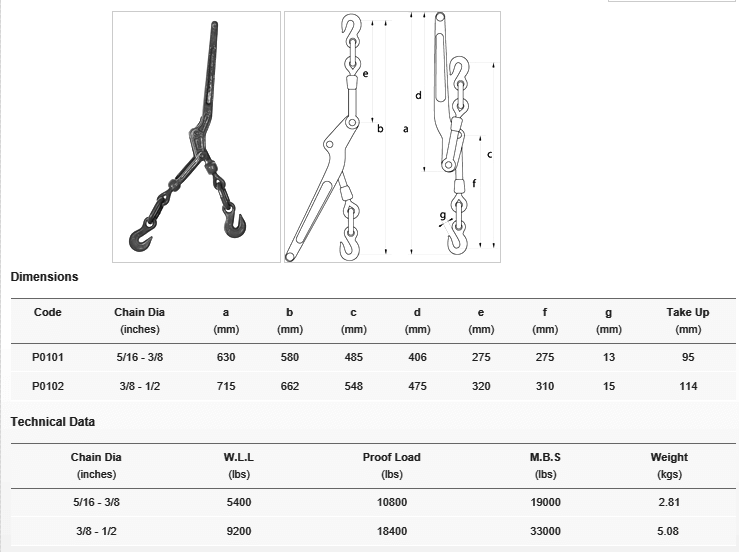

We supply two sizes of lever load binders which have working load limits of 5400kg and 9200kg, the table below shows all the relevant details and dimensions. Chain and hooks can also be supplied to suit the lever load binder and your cargo restraint requirements.

This type of lever load binder needs more effort and energy to operate than a ratchet chain binder. These lever load binders store a lot of energy in the handle when it is tensioned. They have been known to recoil or snap back open which can cause injuries to the user. It is also a major safety issue as the cargo will no longer be held securely.

It is relatively easy to overcome the problem of the recoil issue. Once the lever is tensioned and in its lock down position it should touch the chain. It then needs to be secured. The lever can be fixed back to the chain by using the loose end of the chain, a piece or rope or some soft, strong wire. Rope Services Direct highly recommends using this method of securing the lever load binder every time it is used, not only to protect the user but to ensure the cargo stays securely in place throughout transportation.

Safety Precautions for Load Binders

When using a lever load binder you should always inspect it first to make sure there are no problems and that they are safe to use. If in doubt, don’t use. Look out for cracks and gouges and ensure the WLL markings are readable. Remember to check over the chain and hooks too, a chain with damaged links is not safe to use.

When using a lever load binder you should always inspect it first to make sure there are no problems and that they are safe to use. If in doubt, don’t use. Look out for cracks and gouges and ensure the WLL markings are readable. Remember to check over the chain and hooks too, a chain with damaged links is not safe to use.

You should ensure that the chain and hooks used are compatible with the lever load binder. Having the same WLL and suitable chain size. It is wise to keep out of the path of the moving handle to reduce the risk of injury should it kick back. The lever must be in the correct, locked down position (touching the chain). It must never be tied down in a half mast position.

These lever load binders should never be used for lifting operations. They should never be side loaded (they are designed for straight, in-line use only) and should never be operated whilst standing on the load.

Lever load binders should not be repaired by using any form of heat, welding, heating and bending is not permitted as they will affect the capacity of the lashing operation.

Use caution when releasing a lever load binder. The safest way is to use an open hand under the lever to push it up and open. Use extreme caution as whipping may occur as it releases the tension. Keeping an open hand will protect your fingers!

Lever Load Binder Specifications