- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

£0.75

Why Choose 6 x 19 Plastic Coated Wire Rope? We sell plastic coated wire rop..

£0.24

Picking 7x7 Plastic Coated Wire Rope ConstructionWe sell wire rope tha..

£0.78

7 x 19 Plastic Coated Wire RopeThis type of wire rope delivers the ultimate in t..

£0.30

Perks of 6x7 Plastic Coated Wire Rope Construction There are lots of indust..

Rope Services Direct manufacture, stock and supply robust and stable plastic coated wire rope to help give your operation that extra level of safety. Plastic coated wire rope coated is proven tobe a versatile and robust type of rope and is suitable for both indoors and outdoors use. The PVC coating is added to stainless steel, galvanized steel and nylon and is smooth to the touch and can easily be stripped back where required.

For more information regarding plastic coated wire rope contact Rope Services Direct today. We can discuss your requirements and place an order for whatever length you require, pricing is by the meter.

Wire rope is a strong and robust piece of equipment, and has been designed to stand the test of time. However, given the nature of the industries that this gear operates in, it’s not surprising to learn that wire rope regularly comes under a great deal of stress and strain.

For that reason, it can be a great idea to add a plastic coating to the equipment. It will add greater resistance to abrasion, corrosion, UV rays, and other types of harmful chemicals and elements that are present both indoors and outdoors. For higher pressure applications, or to help extend the longevity of your equipment, we recommend a coating.

This special plastic coated wire rope offers excellent handling properties. This is due to the smooth outer surface of the coating. Plastic coated wire-rope has good flexibility and protection, the coating will offer protection to the wires and strands of the rope, preventing serious damage and kinks from occurring.

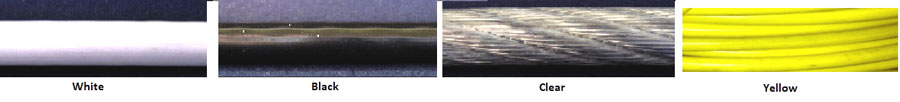

We can also supply any wire-rope with PVC coating in a range of colours. Black, white and clear are the most commonly used coatings. PVC coating is flexible and regularly used to coat the 1x19, 7x7 and 7x19 wire-ropes.

You will find that there are three main types of coating that can be applied to wire rope:

PVC

This is perhaps the most popular type of coating, and is the one that we use ourselves. This is because it is a great, multi-functional, general purpose and low cost material. It’s extremely flexible too.

Polypropylene

Polypropylene is often the recommended choice of protective coating when it comes to wire rope that will be operating in more hazardous environments where corrosion or chemical leaching could occur. This is because the material has a great resistance to these unwanted effects. It is also strong against most forms of abrasion and damage, including impact damage.

Nylon

This is also a flexible, long-lasting and abrasion resistant material. We don’t offer nylon coatings here at Rope Services Direct, but we do stock equipment that is constructed from nylon. Our PVC coating can help add to nylon’s already strong defensive abilities.

As you can see from the above, each of the three main types of coating are extremely similar in nature. All offer many of the same benefits. We have chosen PVC for our customers as it helps to bring a lower cost than some of its counterparts. You can find our contact details at the bottom of this page if you would like to discuss this in greater detail.

What are some of the typical uses and applications that you will find our coatings being used for?

Our plastic (PVC) coated steel wire-rope is suitable for a broad range of applications. They include use as security cables, display cables, guard rails and washing lines as well as in marine environments.

Ideal for outdoor use due to its good UV stability. PVC coated wire-ropes are typically used for. Guard rails, catenary systems, washing lines, abattoir wire, computer security cables, lock cable systems and barrier ropes.

You will often see this type of coated rope as a security system for bicycles and motorcycles as they offer a simple, compact and very effective means of securing their possessions to almost any fixed structure.

The black coated rope is typically used in theatres, TV studios, and concert venues. Theatre cable is also used in other areas where the cabling / wire-rope needs to be unobtrusive and hardly seen for aesthetic reasons. The safe use of lifting equipment is worth a read and offers good guidance.

Whatever your reason for wanting to use PVC coating, you can rest assured that it will provide a strong and long-lasting solution to your existing setup. Designed to stand the test of time, our coatings are some of the finest on the market! To place an order, please call us on 01384 78004 or get in contact with us here.