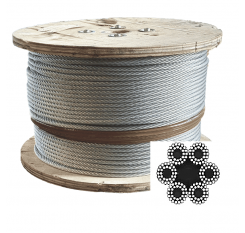

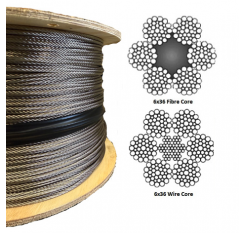

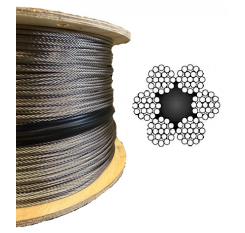

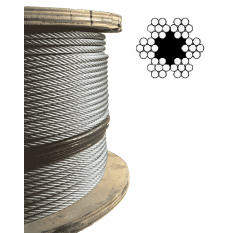

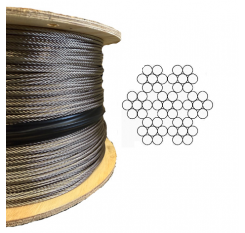

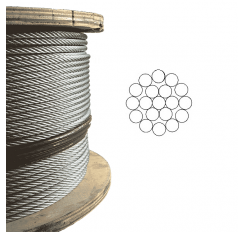

Galvanized steel rope is often used in the industries mentioned because of the added protection given by the galvanization process. Also the wide array of end fixings that can be attached to the rope. These allow easy attachment to most anchor points and some fittings also enable adjustment to the required tension.

Steel W.R can be used alone, or else with other equipment. washing lines, picture hanging, bike locks, barriers, guard rails, hanging shelving, stair rails and even bridge suspension are examples of rope uses. Wire rope cable pullers, winches or a W.R electric hoist, all use galvanized rope. The rope replaces the more commonly seen chain on these types of devices. We can also supply non-rotating wire rope and compacted rope as well as stainless steel wire ropes

Inspecting your Galvanized Steel Cable

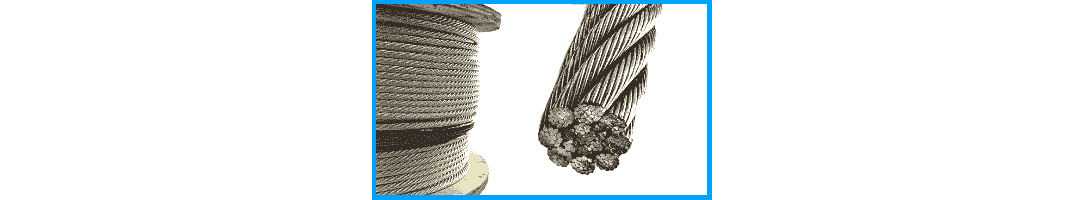

The continuous safe function of lifting equipment utilizing galvanized steel rope, is dependent to a sizeable degree on a solid, regular programme of rope examination by a competent individual. This is to determine any wear, corrosion, wire breaks and distortions that may well influence the safety whilst utilizing the rope. Repairing galvanized steel wire rope can sometimes be an option. Regular inspections will allow any problems to be repaired swiftly, and thus prolong the lifetime of the rope. Failure to examine the ropes on a regular basis might cause injuries. Flaws that could be repaired may be missed. Therefore the rope will probably be beyond repairing and thus unfit for service a good deal quicker.

Listed here are the most typical noticeable signs of deterioration to search for whilst inspecting a galvanized steel rope.

WEAR;

Wear is a normal characteristic of rope service. The usage of the proper rope structure for the purpose proposed should make sure that it stays a less important feature of deterioration. Lubrication will also aid in reducing wear.

BROKEN WIRES;

Broken wires are a normal characteristic near the end of their operational life. Wire breaks in general result from bend fatigue as well as wear. The confined break up of wires might signify some mechanical defect in the equipment. Appropriate lubrication in service will enhance fatigue performance.

DISTORTIONS;

Distortions tend to be the results of mechanical damage, and if severe, may significantly influence rope strength. Observable rusting suggests insufficient lubrication, resulting in corrosion. Pitting of the exterior wires will become evident in certain circumstances. Broken wires eventually result.

INTERIOR CORROSION;

Interior corrosion takes place in several environments when lubrication is insufficient or else of an inappropriate kind. Decreased rope diameter will normally show the observer this condition. Opening it up is the only sure way to confirm internal issues.