- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

POA

The benefits and uses for 6x36 IWRC Compacted Wire Rope 6x36 refers t..

POA

More details on the 8x25 compacted wire ropeRope with the numbers 8x25 has 8 bun..

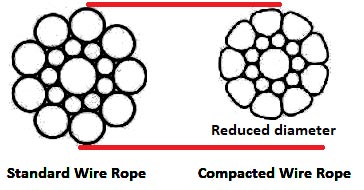

Compacted wire rope refers to a standard rope which has undergone a special process. Rope is either passed through a die or rollers on a special machine to compress the rope. Individual strands can be compacted during the manufacturing process. This process enables either inner strands, outer strands or both to be compacted. A simple/standard compacted rope has a normal inner core but compacted outer strands. Compacting flattens the surface and increases the contact area of all strands.

strands can be compacted during the manufacturing process. This process enables either inner strands, outer strands or both to be compacted. A simple/standard compacted rope has a normal inner core but compacted outer strands. Compacting flattens the surface and increases the contact area of all strands.

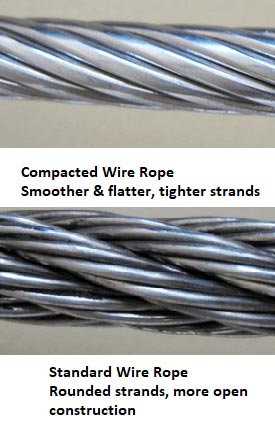

The strands of standard rope are round but after undergoing the compacting process the wires and strands become flattened. Creating a much smoother rope with a smaller diameter.

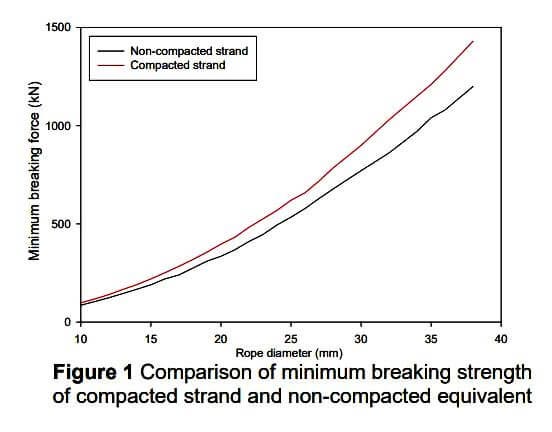

A compacted rope has many benefits when compared to a standard rope. This is due to the special compacting process which reduces the voids within the rope. This therefore increases the cross sectional metallic area resulting in a rope with a higher breaking force factor.

Whilst compacting a rope increases its strength it also reduces its diameter. Meaning that a smaller diameter compacted rope will have the same strength and lifting capacity as a standard, conventional rope with a larger diameter (of the same construction).

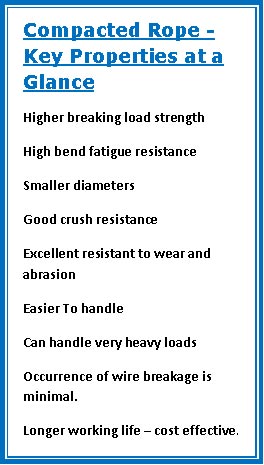

Because the wires and strands are flatter they have more contact area with neighbouring wires / strands. Less friction occurs between them. This is highly beneficial to the wear resistance of the rope. Both internally and externally and also to ancillary equipment.

Because the wires and strands are flatter they have more contact area with neighbouring wires / strands. Less friction occurs between them. This is highly beneficial to the wear resistance of the rope. Both internally and externally and also to ancillary equipment.

Spooling performance of a compacted cable is much improved. Winding this rope on a drum minimises any abrasive wear taking place between the layers of rope. Crush resistance is also a great feature of compacted ropes. Drum winding is also easier.

Bend fatigue resistance is another key benefit to using a compacted rope. Withstanding much more repetitive bending when lifting fluctuating or constant weights. The compacted, flattened strands ensure much less friction/wear to the wires. This occurs when bending over sheaves or in a reeving system which increases the rate of fatigue.

Other benefits include being easier to handle and less harsh to the hands due to their smoothness. They have less constructional stretch and can withstand shock loading. Compacted ropes have a much lower occurrence of wire breakages. This is due to low friction and abrasion between strands. Compacted ropes offer great cost effectiveness thanks to lasting up to twice the life of a standard rope.

Due to the tightly compressed strands these ropes have some corrosion resistant qualities. They are able to resist dirt ingress and minimise the ingress of other harmful substances between the wires. They are easier to clean and inspect too.

Compacted Rope Uses

Compacted rope can be used for most types of crane ropes and are often recommended due to their excellent properties as discussed above. We offer the 3x36 compacted rope and the 8x25 compacted rope with many diameters available. They are ideal for heavy lifting applications and special operations requiring high breaking loads and bend fatigue resistance. Traditional rope does not usually offer this resistance.

Typical uses include pillar deck rope, off-shore crane rope, deck crane rope, whip hoist rope, tower cranes, mobile cranes, container cranes , hoist ropes, aesthetic purposes and more.

Rope Services Direct are able to supply any type of compacted rope at affordable prices, please contact us if you need any more information.