- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

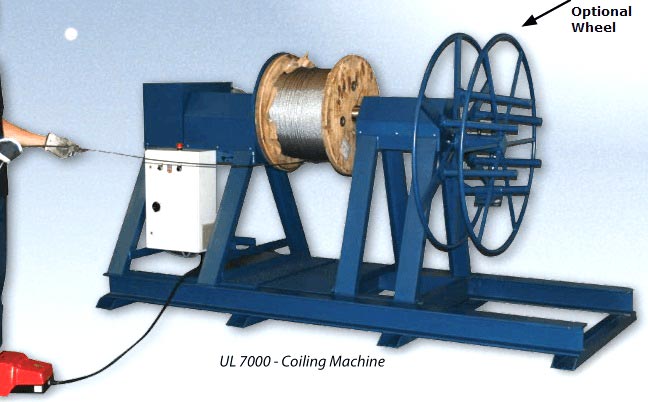

We can supply two varieties of coiling machine. With maximum loads it can handle up to 7000kg, please see below for full details.

Both coiling and reeling wire rope can cause serious damage to the rope if it is not carried out following correct procedures. Re-winding can cause just as many issues!

When you are removing wire rope from a drum or reel you should take necessary precautions to protect yourself and the rope. Firstly you should wear protective gloves and any other protective equipment you see fit. The rope should NEVER be thrown in turns from the reel. This can cause many issues to yourself. Including injuries from sudden kickbacks and recoiling. And to the rope; kinks can develop as well as unwanted turns both of which can render the rope unusable. The wire rope should be paid out gently from the reel by holding the end and walking in a straight line. This is where common rope issues can begin when incorrect methods of unreeling are used. Hoisting issues, rope failure, rope damage and premature replacement rope are some problems arising from bad unreeling techniques.

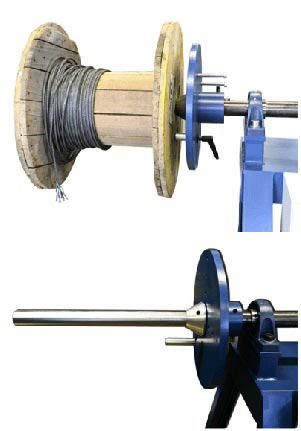

In order to carry out this process correctly the drum/reel should be raised from the ground and supported in a way so that the drum can reel freely. The coiling machines and reeling machines that we offer are made just for this task.

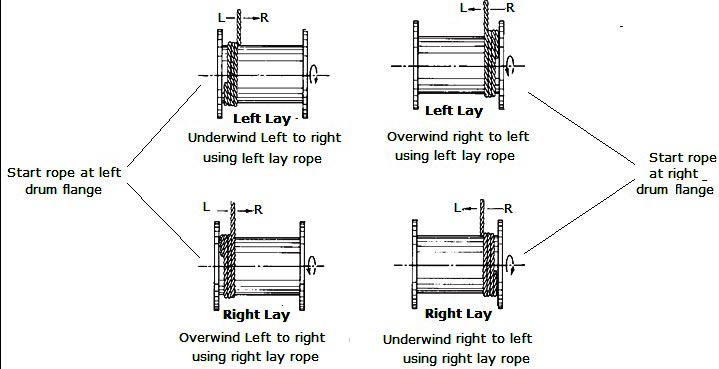

It is worth keeping in mind that when you are re-reeling wire rope back onto a reel just as much care should be taken to protect the rope. It should be wound in the same way as it came off a drum. In order to prevent reverse bending of the rope which can cause damage beyond repair. If the rope is wound onto a reel the opposite way to the direction it was originally wound the first layer will begin to spread out openly across the reel. This will create gaps between the turns of rope. Which will consequently be filled by the next turn of rope. This will cause crushing and flattening problems as more layers are wound unevenly. Always pay close attention to the lay of the rope.

The rope must be kept taught and wound in tight and even layers ensuring they lay snugly against each other, because if they are wound loose the rope will be open to friction issues, causing damage, wind the rope too tightly and the under layers of wire rope will be open to crushing issues. When you are re-reeling rope from one drum to another you should wind from the same direction; i.e. from the top of one reel onto the top of the other reel. The reel’s shaft should be in a horizontal orientation. Vertical re-reeling may be done with great care but is not recommended without the correct equipment because it is much more difficult to keep the wire rope tight and it may drop over the lower reel flange and drop to the floor.

Wire rope coiling machines are undoubtedly the best and easiest way to coil and uncoil wire ropes whilst minimising the risk of damage to the rope and injury to yourself. Remember all machinery should follow the LOLER regulations. Get in touch with Rope Services Direct for more information. Full product specifics detailed below.

This device is intended to be used as a standalone coiling machine, but can be used alongside other parts for a complete wire rope handling system including coiling and uncoiling, measuring and cutting. There are two capacities available, the UL800 for 800kg and the UL1200 for 1200kg. Both are foot controllable, with the controller connecting to the main machine with a flexible cable offering many operating possibilities.

This device is intended to be used as a standalone coiling machine, but can be used alongside other parts for a complete wire rope handling system including coiling and uncoiling, measuring and cutting. There are two capacities available, the UL800 for 800kg and the UL1200 for 1200kg. Both are foot controllable, with the controller connecting to the main machine with a flexible cable offering many operating possibilities.

This device has adjustable internal diameter and coil width facilities. Wood reels may be used if the diameter is under 900mm and the width under 400mm. The diameter of the rod is 50mm maximum.

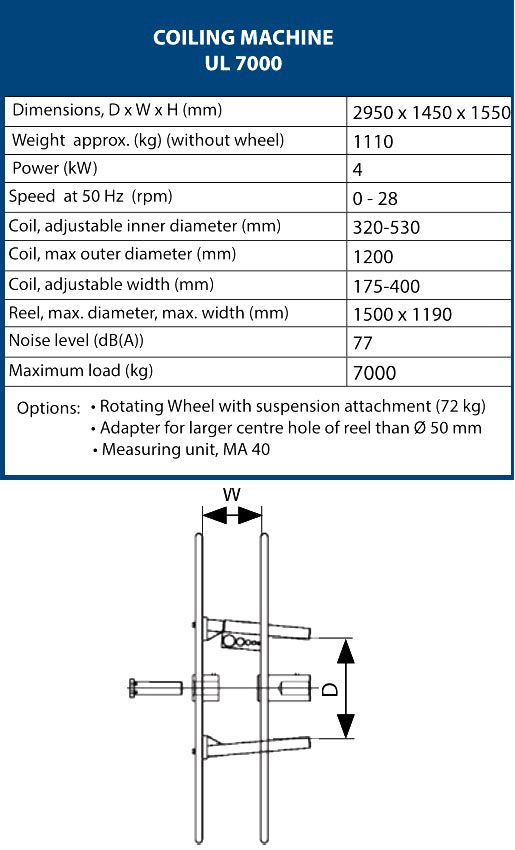

This coiling machine can be used as a standalone coiler or it can be integrated into a complete uncoiling, cutting, measuring and coiling system. The UL 7000 may be used for coiling in a vertical position as well as standard reel coiling. The reels are secured by a hydraulic clamping system operated via the control unit where the speed can be set manually. (variable speed)

This coiling machine can be used as a standalone coiler or it can be integrated into a complete uncoiling, cutting, measuring and coiling system. The UL 7000 may be used for coiling in a vertical position as well as standard reel coiling. The reels are secured by a hydraulic clamping system operated via the control unit where the speed can be set manually. (variable speed)

Incorporating a foot control unit the Ul700 coiling machine enables flexible operation. The start & stop functions are simultaneously controlled on integrated machines.

These machines are capable of handling wire rope with diameters from 6mm up to 80mm. (There is an additional arm with track wheel dimensions of 500mm is available separately). A rotating wheel with six arms can be fitted by removing the reel. The internal coil diameter and coil width are adjustable. The wheel can be hung onto the side when not in use.

There are no products to list in this category.

There are no products to list in this category.